STRAIGHTENING WOOD SHAFTS

Getting wood shafts straight and keeping them straight is an age old problem

that hasn't much in the way of progress over the last 30 years. Most of the

information that will be provided has been around for many decades. If you

are the type of person who insists on having perfectly straight shafts for

target shooting or hunting, then do yourself a favor and buy a good set of

aluminum shafts. They are even making aluminum that kind of looks like wood.

The reality is that to get good arrow flight and consistency within the limits

of ones shooting ability, wood shafting is very satisfactory. If you plan on

making custom arrows with crests with fine lines, you will find that you need to

have the shafts pretty straight to get smooth, consistent crests.

First, how can you tell if a wood shaft is straight or not. We each have

our own God-given straightness gauges built into our bodies in our senses of

sight and touch. You can very easily sight down a shaft (put the end up to

your eye) and you will find that variations in straightness are quite evident.

There is another method that uses our sense of feel. If you are right-handed,

touch your fingernail tips of your thumb and middle finger together in the form

of a shallow "V". Hold one end of a shaft with your right hand and

place the middle of the shaft in the "V" formed by the fingernails of

your left hand. Now give the shaft a sharp clockwise spin with your right

hand. You can easily feel if the shaft is true or not. Try it first with a

straight aluminum arrow and you can feel how smooth the shaft turns in your

hand. Getting all of your wood shafts to spin as smoothly as an aluminum

shaft is probably not realistic. However, using the following methods you

should be able to get the shafts where they will spin relatively smooth in your

hand. You can also use other methods such rolling the shaft on a flat surface

such as glass or with a commercial shaft straightener with a dial indicator to

check the shaft straightness. I think that this is probably overkill.

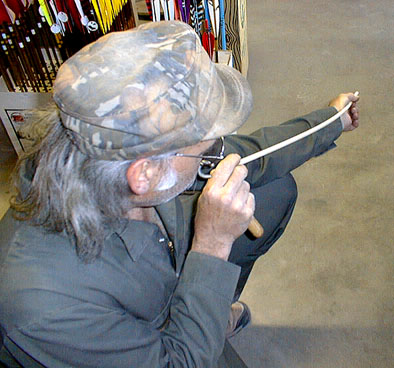

Method #1 - Hand Straightening -

This is probably the method used by most people and is a method that you can

always use in the field with finished arrows that sometimes want to revert to

their pre-straightened state. Sight down the shaft and locate the bend in the

arrow. Using the heel of your hand, bend the shaft in the opposite direction

of the bend. This is a process of several iterations; keep doing it and

checking the straightness using the above method until you get the shaft

straight. (photo above) It takes some practice, but after a while

you will find yourself pretty proficient at it. This is often a temporary

solution, particularly with hard woods. Some of the softer woods will accept

this method and remain straight, others will revert back to some degree of their

previous shape.

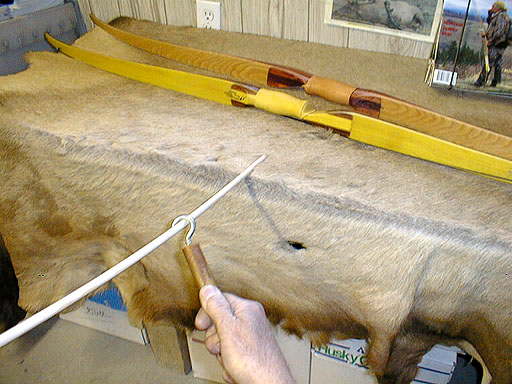

Method #2 - Hooking - This method

uses a hand tool to burnish or compress the wood on the high side of the arrow.

First you must find the high side or outside of the bend of the shaft using any

of the methods described above. Mark the location of the outside of the bend

with a soft pencil. Using the hook (photo above) rub the shaft with

the hook along the outside of the bend. Use moderate pressure at first and

continually check for straightness. As you get closer and closer to the desired

degree of straightness, you can decrease the pressure and the number of strokes.

A hooking tool can be easily made by using a piece of dowel and a cup hook.

This method compresses the fibers of the wood on the outside of the bend of the

arrow and will bring the alignment back to straight. This method is more

lasting than the hand-straightening method, but may not be permanent. It is a

good idea to always keep an eye on your finished shafts to make sure that they

are straight.

Method #3 - Heat - You can use

either of the above methods by first applying heat. This is probably more

appropriate for hard woods such as ash, hickory, maple, etc. rather than the

soft pines and cedars as it is much easier to scorch them. A good way to apply

heat is by using a wood burning stove. If the stove is very hot, you have to

watch that you don't burn the shafts. My stove has an artificial marble top

that doesn't get real hot and works very good for heating up shafts. Another

method that works pretty good is to use a hair dryer. Just don't let your

wife catch you heating up wood shafts with her good hair dryer. In Glenn St.

Charles' book From Billets to Bows, there are some interesting

old letters from Saxton Pope about building arrows. He advises in 1921 to heat

birch shafts over a gas stove or a fire to straighten them.

There are a few products that are advertised now and then for straightening

wood shafts. There is presently a product being advertised as the Shaft Tamer.

It is really a tool that compressed the wood fibers much like the hook.

Instead, this product is a solid steel cylinder about 2" in diameter and

4" long. In the middle around the circumference of the cylinder there is

a polished groove. You use this cylinder to rub the surface of the high side

of the shaft as you would with a hooking tool.

Not all dowels are suitable for arrows. Occasionally, you will get a shaft

that you cannot straighten no matter how you try. These make good tomato stakes

or tests for stains, finishes, etc. Most reputable suppliers of shafts will

not send you shafts that are this bad. They will cull the bad ones and provide

you only with shafts that are reasonably straight that you can improve on with a

little work. In every batch of shafts that you buy there are some that are

near perfect. Put a mark on these so you can tell which ones they are. Save

these for your most prized hunting arrows.

|