The $18 Cresting

Machine

text and photos courtesy of Ron Shealer

The $18 Cresting

Machine

text and photos courtesy of Ron Shealer

The following gives your some instructions on how to make

a low cost cresting machine which nearlyh everyone can make at

home - provided you have a few basic hand tools such as a saw,

file, and a drill. I put this information together for my students

at school and my fellow traditional archers visiting the Stickbow.

The original power unit is a sewing machine motor complete

with the foot peddle control. I bought this motor and peddle

at a sewing machine repair shop for $15. I told the shop owner

I was building a project and asked if he had a motor and peddle

control off of a used sewing machine. He had several to chose

from.

After cresting a dozen arrows with the peddle control I decided

to try a dimmer switch for greater control of the turning speed.

A stop or control could be added to the peddle assembly but by

chance I had a dimmer switch/rheostat which wasn't being used.

The dimmer switch worked great, but be sure to turn it completely

off or unplug the motor when not in use as the switch could heat

up over time.

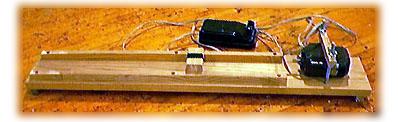

The main chassis of the cresting

machine is a pressure treated 1" X 6" plank. I just

happened to have some scrap left over from a deck project. There

is nothing special about the wood, plywood can also be used.

The overall length needs to be longer than the arrows you are

working with as you will have to mount the motor on the board

and you may want to mount a control switch on the base. A light

could also be added to the machine if you really want to be fancy.

If you need somewhere to store your freshly crested arrows you

could add a piece of 2" x 4" with holes to stand your

shafts on end while they dry, I plan to add this feature later

on.

The main chassis of the cresting

machine is a pressure treated 1" X 6" plank. I just

happened to have some scrap left over from a deck project. There

is nothing special about the wood, plywood can also be used.

The overall length needs to be longer than the arrows you are

working with as you will have to mount the motor on the board

and you may want to mount a control switch on the base. A light

could also be added to the machine if you really want to be fancy.

If you need somewhere to store your freshly crested arrows you

could add a piece of 2" x 4" with holes to stand your

shafts on end while they dry, I plan to add this feature later

on.

Under the main body I put two small strips of wood as feet.

This allows the cords to be placed under the whole assembly and

out of the way. I also mounted small rubber feet under the base.

I drew a center line on the board and mounted my motor in line

using two carriage bolts with wing notes. (Carriage bolts and

rubber feet $3) The bracket over the top of the motor has some

foam tape on the hidden side to help hold the motor in place

and dissipate any vibration.

Motor Mount

I made guide rails that are approximately 3/4" square

and nearly the length of the working base. If you do not have

access to a table saw to make the rails, some square trim found

at most lumber stores will work ( angle iron or aluminum will

also work). These rails contain the sliding block that supports

the arrow shaft. This sliding block can be moved from end to

end to account for shafts that may not be true. The sliding block

has a "v" cut into it to hold the shaft. I used a table

saw to cut the v but a hand saw or file should do the same job.

The "v" was then lined with felt. Felt "v"

blocks can also be purchased from some traditional equipment

suppliers. One fellow archer recommended using a small cloth

bag filled with lead shot to hold the arrow down in the "v"

block. Although I have yet to try this myself I think this would

be an asset as you would then have two hands free to do the cresting,

make adjustments, etc.

Sliding V-Block

Sliding V-Block

Coupler made from surgical tubing

The arrow attaches to the motor by sliding a piece of surgical

tubing over the motor shaft and the nock or taper of the arrow

to be crested. This joint works well but it is sometimes challenging

to get the tubing over the arrow nock. If you are going to use

this type of coupler it may be best to crest your arrows prior

to gluing on the nocks. The tubing will slide onto the taper

easier than the nock. I was just looking for something quick

and simple. Couplers are available from a few of the traditional

equipment suppliers. A coupler could also be made on a metal

lathe with a set screw at one end to lock to the motor shaft

and an internal o-ring on the other end to grip the nock.

HAPPY SHOOTING!

Special thanks to

all of the Leather Wallers that passed on tips and suggestions.