SHAPING THE BOW

The last photo in the previous segment showed a bow that has just been

removed from the form. The next step, in the bowbuilding process,

will be to remove the excess glue from along the bows edges. At the

same time you will need to square up the blank, to make it possible

to mark the bows longitudinal centerline. You can use a hand sander,

filers or rasps to accomplish these two tasks.

It is vital that an accurate centerline is drawn. This can be

accomplished in several ways. The following photo shows a recurves

centerline being draw using a wood block of the appropriate thickness.

By sliding the block down the limbs back, along the flat surface,

a centerline can be accurately marked. You can also use a long straight

edge which can be clamped to the bow or you can use a piece of string stretched

from limbtip to limbtip. If the centerline is not accurate, limb

twist will be built into the bow.

Once an accurate centerline has been established, the bows pattern will

need to be transferred to the back of the bow. The pattern pictured

below is made from a fiberglass strip, however wood patterns work as well.

Please note the holes drilled along the centerline of the pattern, as well

as the string groove line marked across the pattern near the tip.

The holes allow you to see through the pattern and make sure that alignment

of the pattern on the bows limbs is accurate.

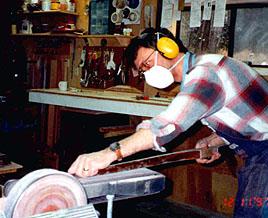

Once the pattern is transferred to both limbs, the excess material can

be removed. On longbows, I prefer to use a bandsaw for this step

although sander and files can also be use. The following photo is

self-explanatory, however I would like to draw your attention to the respirator

and hearing protection. Many processes in a bows construction result

in fiberglass, wood and glue dust, none of which are healthy to breath,

so please us the necessary safety precautions. I always wear hearing

protection as well, since I can't image what it would be like not being

able to hear an elk bugle or the grunt of a buck. OK, enough

lecturing.....:-)